CUTTING WHEELS

For cutting glass, ceramics, crystals, and metals. Available in various diameters/thicknesses for precision cutting solutions.

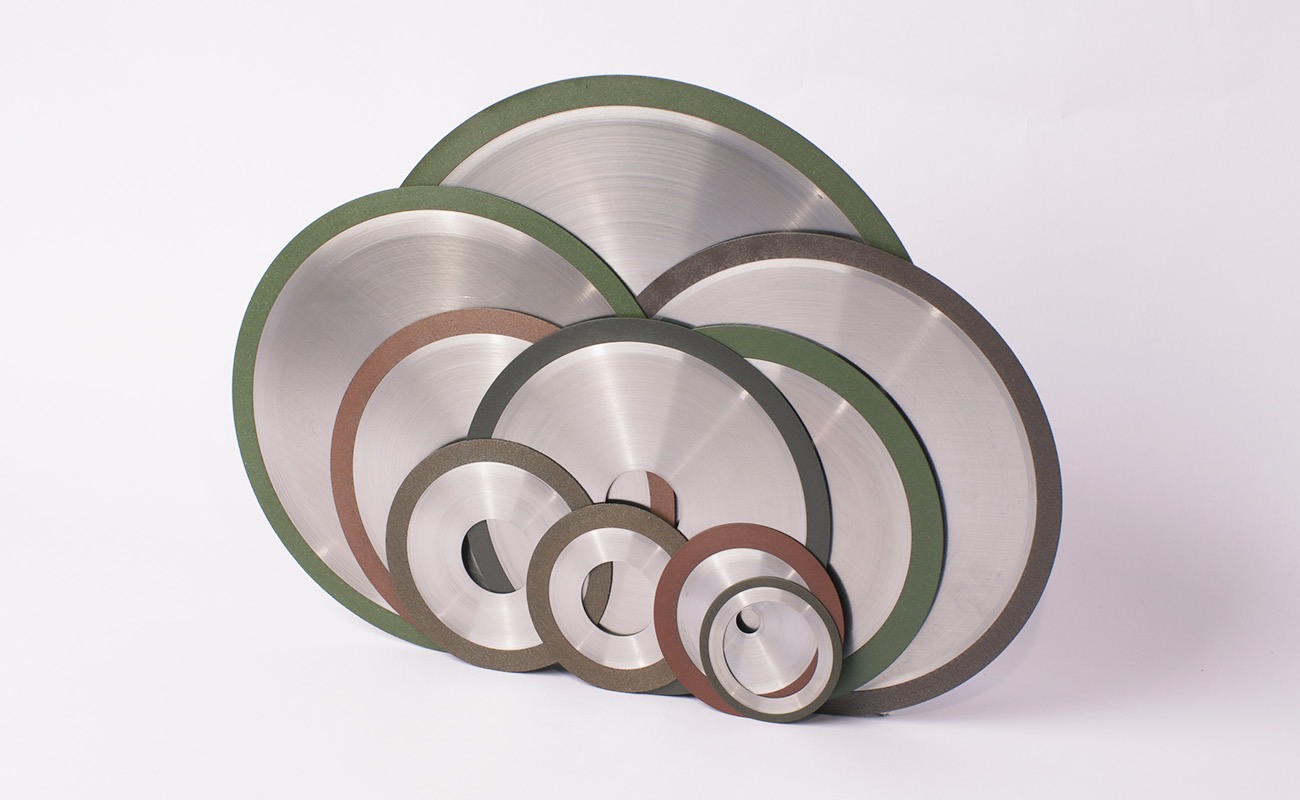

View MoreMETAL BOND GRINDING WHEELS

For precision edge grinding of glass, stone, and engineered quartz,these wheels are ideal for single-edge, double-edge, and shape-profiling glass grinding machines.

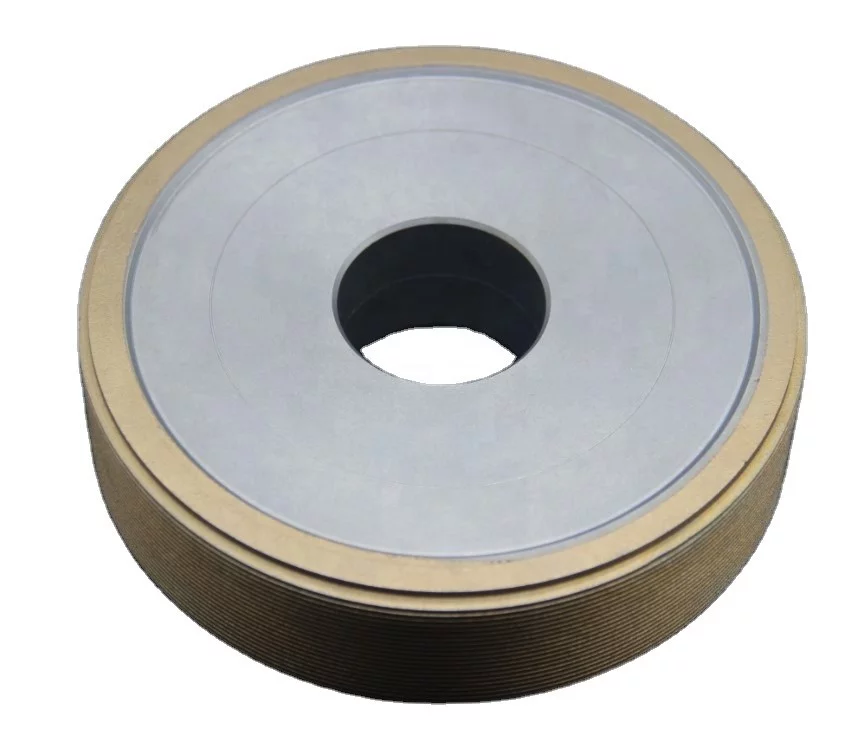

View MoreRESIN BOND GRINDING WHEELS

For high-speed grinding of tough materials like stainless steel & titanium. Perfect for aerospace & precision tool manufacturing.

View MoreELECTROPLATED GRINDING WHEELS

High-performance and sharp, excellent for intricate grinding tasks, offering superior cutting performance in tool manufacturing & electronics.

View MoreGRIND KNOW

Your Hub for Grinding Solutions & Knowledge, you will find your grinding solution here.

Study NowGrind with Passion, Achieve with Aim | aimgrind.com

Why Aimgrind

We have been focusing on customized grinding wheels and abrasive tools for more than ten years, providing personalized selection and formula design for the grinding needs of different materials such as metals, ceramics, composite materials, etc. From vibration control, burn prevention to life extension, we provide a full process service of problem diagnosis → parameter matching → sample optimization to ensure that the grinding wheel is perfectly matched with your equipment and process.

CATEGORIES

OUR PRODUCTS

Customized grinding wheels and abrasive tools are available

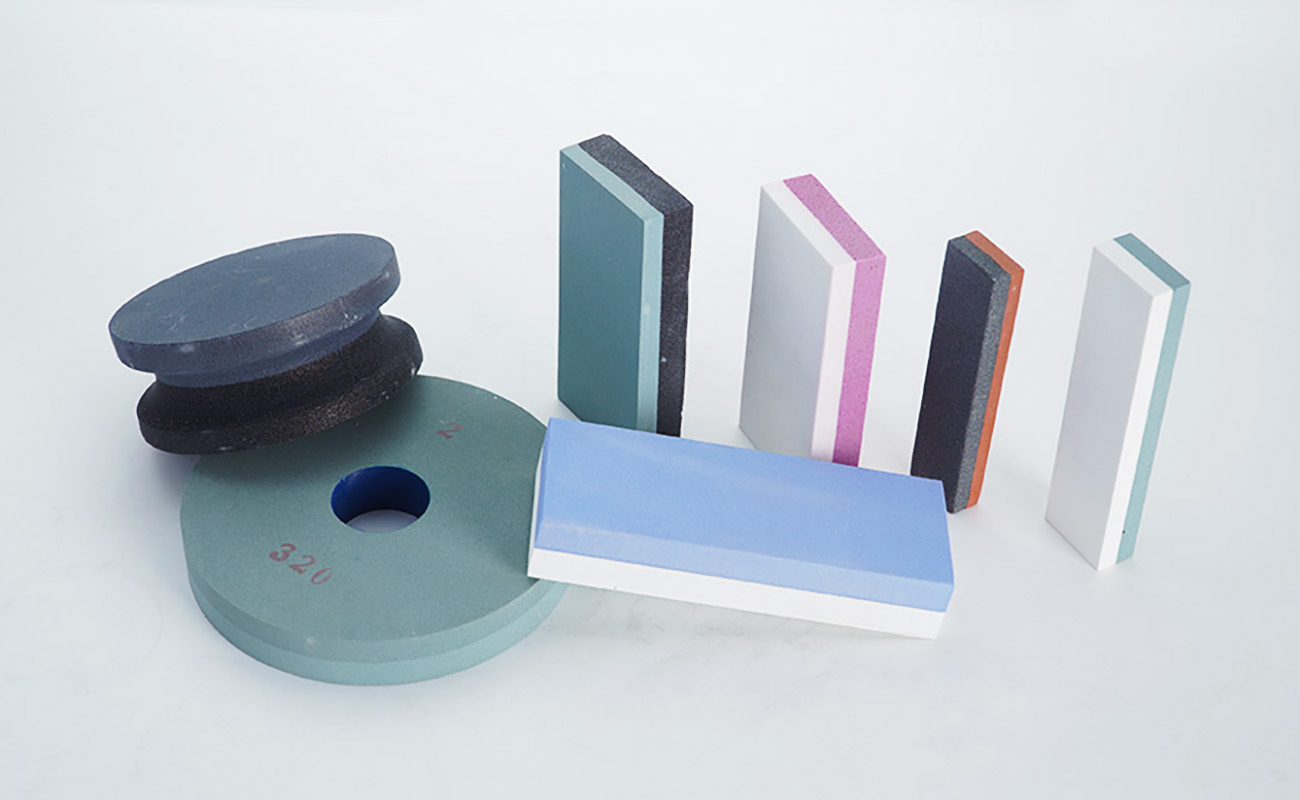

Silicon Carbide Grinding Wheel

Silicon carbide grinding wheels are ideal for grinding soft metals (such as cast iron and aluminum) and extremely hard materials (such as cemented carbide). They significantly feature excellent heat conductivity, pure silicon carbide grinding, lower grinding cost & dressing frequency, high productivity, shorter grinding time, and excellent surface finish.

SG Grinding Wheel

SG Grinding Wheel is a high-quality abrasive prepared by a sol-gel method which is also considered as a sintered abrasive. It is a high purity abrasive with a submicron crystalline structure from a seeded gel sintering process. Compared to other grinding wheels, this SG grinding wheel has a ceramic abrasive which 5-10 times more durable and wear-resistant because of its corundum particles. This super durable tool is the best choice for precision grinding for unhardened and hardened steels like cast iron, carbon steels, alloy steels, tool steels, and many more.

CBN Grinding Wheel

CBN grinding wheels, Grinding Wheels, Super hard Abrasives, Uncategorized, Vitrified bond grinding wheels

CBN grinding wheels are perfect for grinding hard-ferrous materials, bearing steel, hardened steel, nickel-based alloys, etc., due to how they are characterized by high chemical resistance and thermal stability. They significantly feature long service life, minimal heat and dust, support for wet and dry grinding, and safety.

Diamond Grinding Wheel

CBN grinding wheels, Diamond grinding wheels, Electroplated bond grinding wheels, Grinding Wheels, Super hard Abrasives, Uncategorized

Diamond grinding wheels are ideal for grinding high hard hardness brittle materials and not general steel or other soft materials. They are structured by a transition layer, diamond abrasive layer, and matrix. They significantly feature high grinding efficiency, long service life, high abrasion resistance, impressive cutting performance, and good thermal conductivity.

Resin Diamond Glass Wheel for Edging Machine

Grinding Wheels, Diamond grinding wheels, Resin bond grinding wheels, Super hard Abrasives, Uncategorized

Resin diamond glass wheel for edging machine is made of high-grade diamond materials to function effectively in fine grinding, which is ideal as far as imported and domestic straight-line edging machines and double-edging machines are concerned. This tool is characterized by good sharpness and no edge chipping, excellent thickness, great grinding performance, better wear resistance, and long service life.

GRIND KNOW

Your Hub for Grinding Solutions & Knowledge

Grinding Wheel Selection Guide: Comprehensive Considerations for Grinding Factors

March 1, 2024

No Comments

Introduction As the core tool in grinding processes, grinding wheels directly affect processing quality, efficiency, and costs. Therefore, when selecting

Causes and effects of grinding wheel wear resistance

November 28, 2023

No Comments

Grinding wheel wear is an inevitable phenomenon during use. Whether it is ordinary grinding, high-speed grinding, or heavy-duty grinding, the

6 factors affecting the quality of grinding wheels

November 27, 2023

No Comments

The quality of the grinding wheel depends on a variety of factors, including the material, structure, manufacturing process, grain size,

FAST DELIVERY

7~10 Days Delivery Time

GIVE US A CALL

+86-13733809594

CONTACT US

brian@aimgrind.com

LOCATIONS

No. 57 Kexue Avenue, Zhengzhou, Henan, China